Hinge Body And Accessories Stamping

Hinge body and accessories stamping is a vital manufacturing process. For hinge bodies, suitable metal sheets are chosen and shaped by precisely designed dies in stamping presses. Accessories like pins and washers are also stamped with strict tolerances. Quality control checks dimensions and material quality. It’s crucial for creating reliable hinges used widely in furniture and more industries.

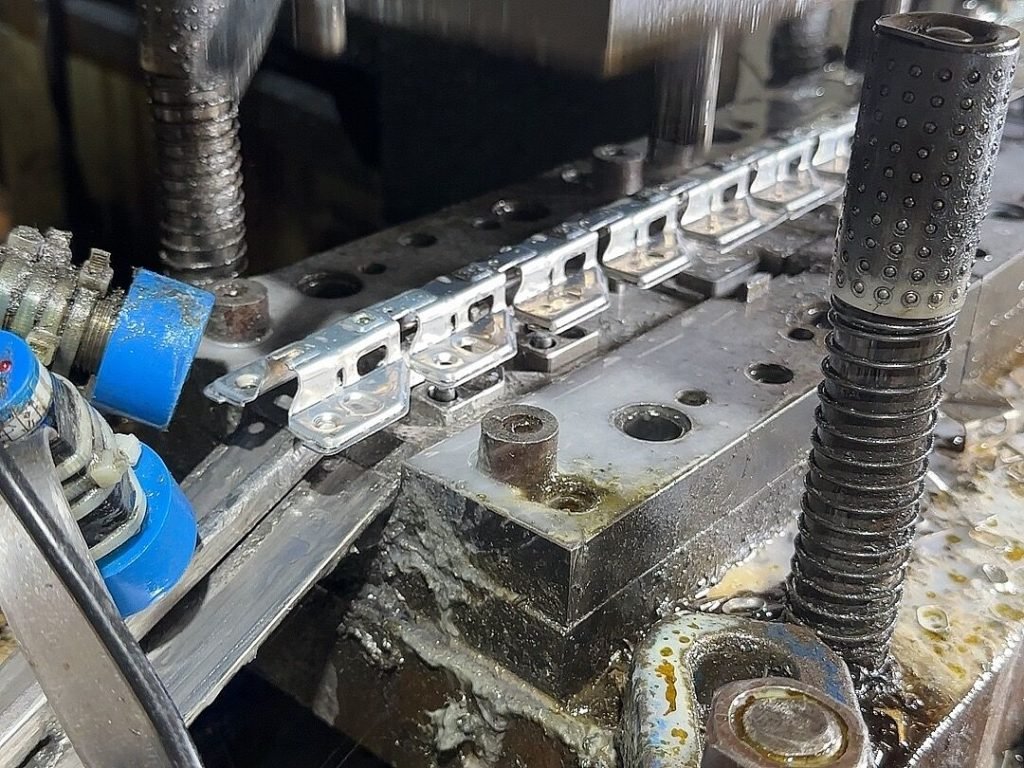

Hinge Base Stamping

Hinge Base Stamping is an important manufacturing process. First, appropriate metal materials are selected based on the requirements. Then, specialized dies are crafted to define the shape. The metal is placed in a stamping press, where force shapes it into the hinge base. Quality checks ensure its precision. It’s key for making sturdy hinges used in various products.

Hinge Manual Assembly

Hinge manual assembly is a meticulous process. Workers first gather the stamped hinge body, pins, and other accessories. They carefully insert the pins into the corresponding holes of the hinge body, ensuring a proper fit. Washers are added if needed for smooth operation. Attention to detail is crucial as any misalignment can affect the hinge’s functionality, vital for cabinets, etc.

Automatic Hinge Assembly

Automatic Hinge Assembly is a modern and efficient manufacturing method. automated systems are programmed to handle the task. They precisely pick up the hinge components like bodies, pins, and accessories. With accurate positioning and insertion, the assembly process is completed swiftly. It boosts productivity and ensures consistent quality for hinges used in diverse applications.

Hinge Automatic Packaging

Hinge automatic packaging is a streamlined process. Specialized machinery is employed to handle it. Hinges are first sorted and counted accurately. Then, they are placed into packaging materials like bags or boxes. The automated system seals and labels them precisely. This ensures efficient packaging, protects the hinges during transit, and readies them for market distribution.

Hinge Storage

Hinge storage plays a crucial role in the production chain. Adequate storage areas are set up with proper racks or bins. Hinges are categorized based on types, sizes, and qualities. The environment is kept dry and cool to prevent rust or damage. Regular inventory checks are conducted to ensure easy access and availability when needed for further manufacturing or sales.

Hinge Shipment (FOB SHENZHEN OR SHANTOU)

Hinge shipment (FOB SHENZHEN OR SHANTOU) is a significant stage. Goods are first transported to the ports of Shenzhen or Shantou. After proper inspection and documentation, they are loaded onto the designated ships. The FOB terms clarify responsibilities, with risks transferring upon shipment. It enables smooth export, connecting manufacturers to global markets efficiently.